Welcome To Ignite Polymers

We operate a state-of-the-art, fully automated dry mortar plant with an annual production capacity of 32,000 metric tons. Our three manufacturing units, located in Karnal, Gurugram, and Rudrapur, ensure the highest quality and performance of our specially formulated products. Additionally, our epoxy plant can deliver up to 1,000 tons of epoxy grout each year.

Production

We are pursuing export opportunities in SAARC countries as part of our commitment to global expansion. In line with this goal, we have obtained the European Standard CE certification to ensure the quality of our products.

Global Presentation

We have made significant investments in research and development to produce a top-quality, certified product range. Drawing on decades of industry experience and materials research, we've established a state-of-the-art lab equipped with modern technology.

Research & Development

We create innovative solutions for various construction segments and related sub-industries by blending chemicals, natural, and renewable raw materials. Our deep knowledge and expertise in specialized building chemicals are applied across the following industries.

Our Product Categories

- - AAC Block Adhesive (B.J.M.)

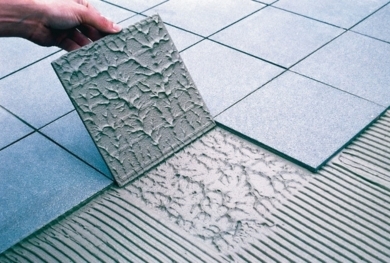

- - Tiles Adhesive

- - Tile Stone Fixing Solutions

- - Epoxy & Grouts

- - Superb Flax 369

- - Walling Solutions

- - Water Proofing

- - Cleaners & Tools

We have fleet of 3 commercial vehicles and a large modernized Logistic system to ensure delivery on time.

Our after Sale service is our unique feature which improve customer retention and increase the likelihood of customer parching from us again or referrals business.

Services

The lightweight characteristic of certain building materials is achieved through environmentally friendly chemical reactions during their manufacturing process. For example, in the preparation and pouring of these materials, aluminum powder is typically added. This aluminum powder reacts with calcium hydroxide (derived from lime) and water to produce hydrogen gas. In an alkaline environment, this reaction between aluminum and calcium hydroxide creates bubbles within the mixture. These bubbles are uniformly distributed, causing the material to expand and foam. This expansion process resembles the rising of bread dough and significantly increases the volume of the material. The hydrogen gas bubbles contribute to making these materials much lighter compared to traditional concrete, weighing only about 20% as much. This lightweight property not only facilitates easier handling and installation but also reduces the overall load on structures. This allows for greater design flexibility and potential savings in foundation and structural support construction, making it a sustainable choice for environmentally conscious building projects.

Eco Friendly Green Product

Our Solutions

AAC Block Adhesive

Tile Adhesives

Epoxy & Grouts

Walling Solutions

Water Proofing

Cleaners & Tools

Superb Flax 369

Tile Stone Fixing Solutions